Gordon Robertson

GRIPPER PROJECT

I worked in a team of five to design a light motor-powered gripper capable of holding a two pound object under a lot of centripetal force with a limited budget and tight deadlines. If the object dropped 0.1 inches, the group failed. We were among the first three groups to have a functional gripper.

DESIGN

I designed almost all of the parts in Solidworks.

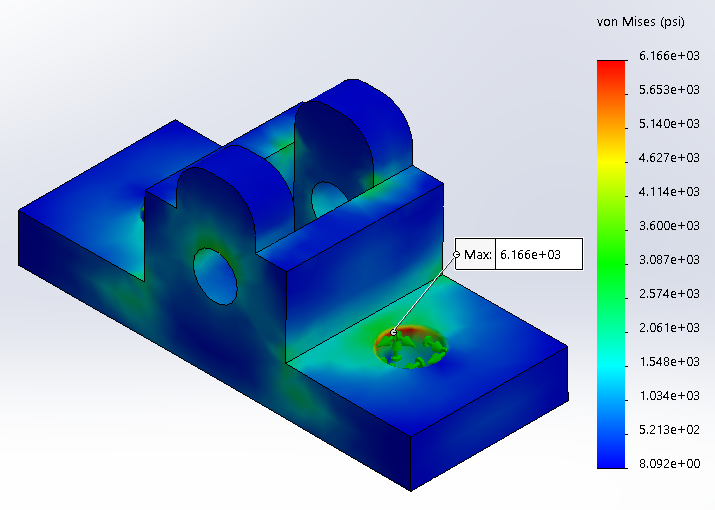

FEA was used to ensure no part would fail

The 3D printed parts were oriented so that they were strong enough in each direction to avoid failure

The design of each of the parts accounted for the error of their manufacturing process.

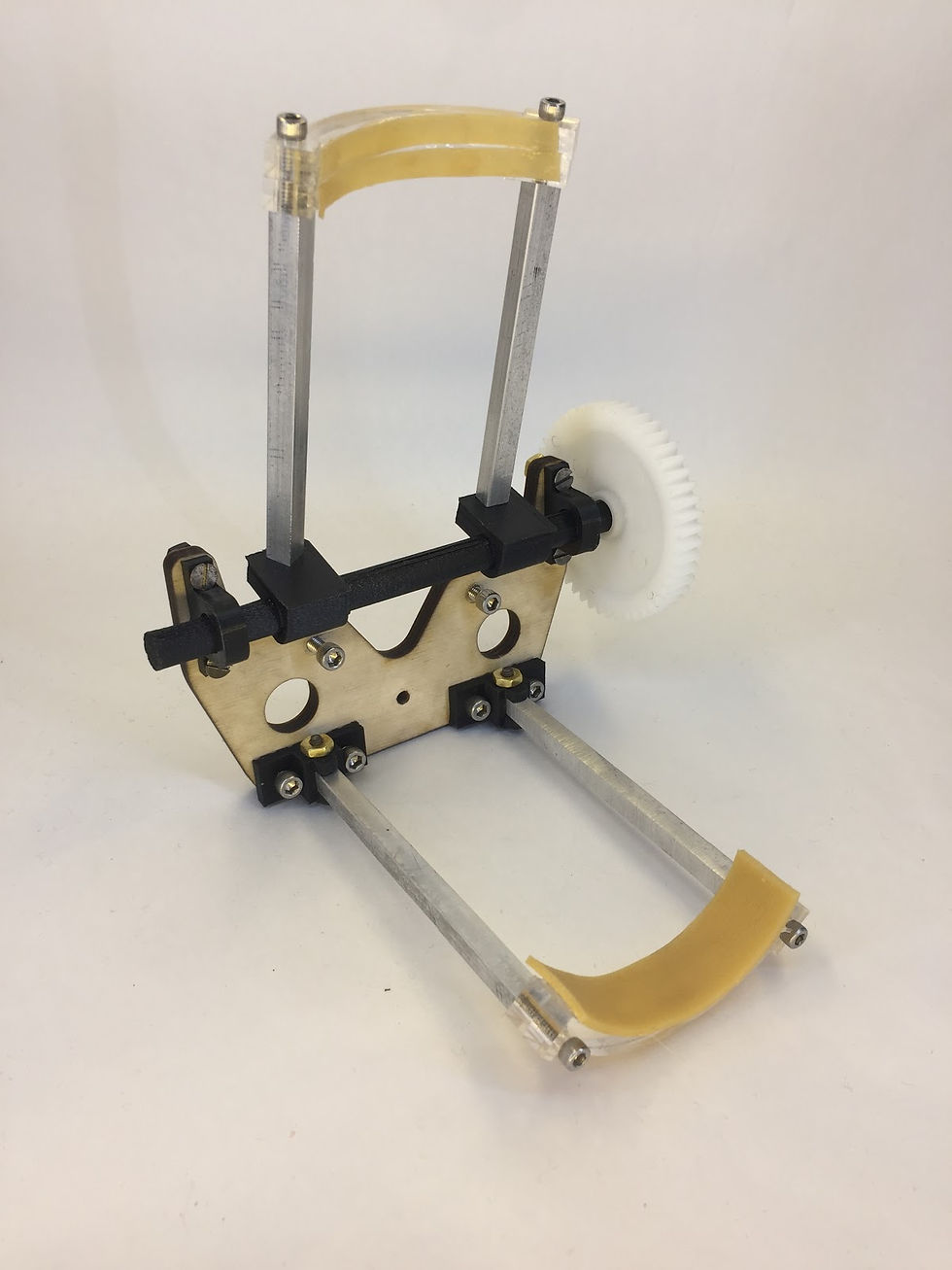

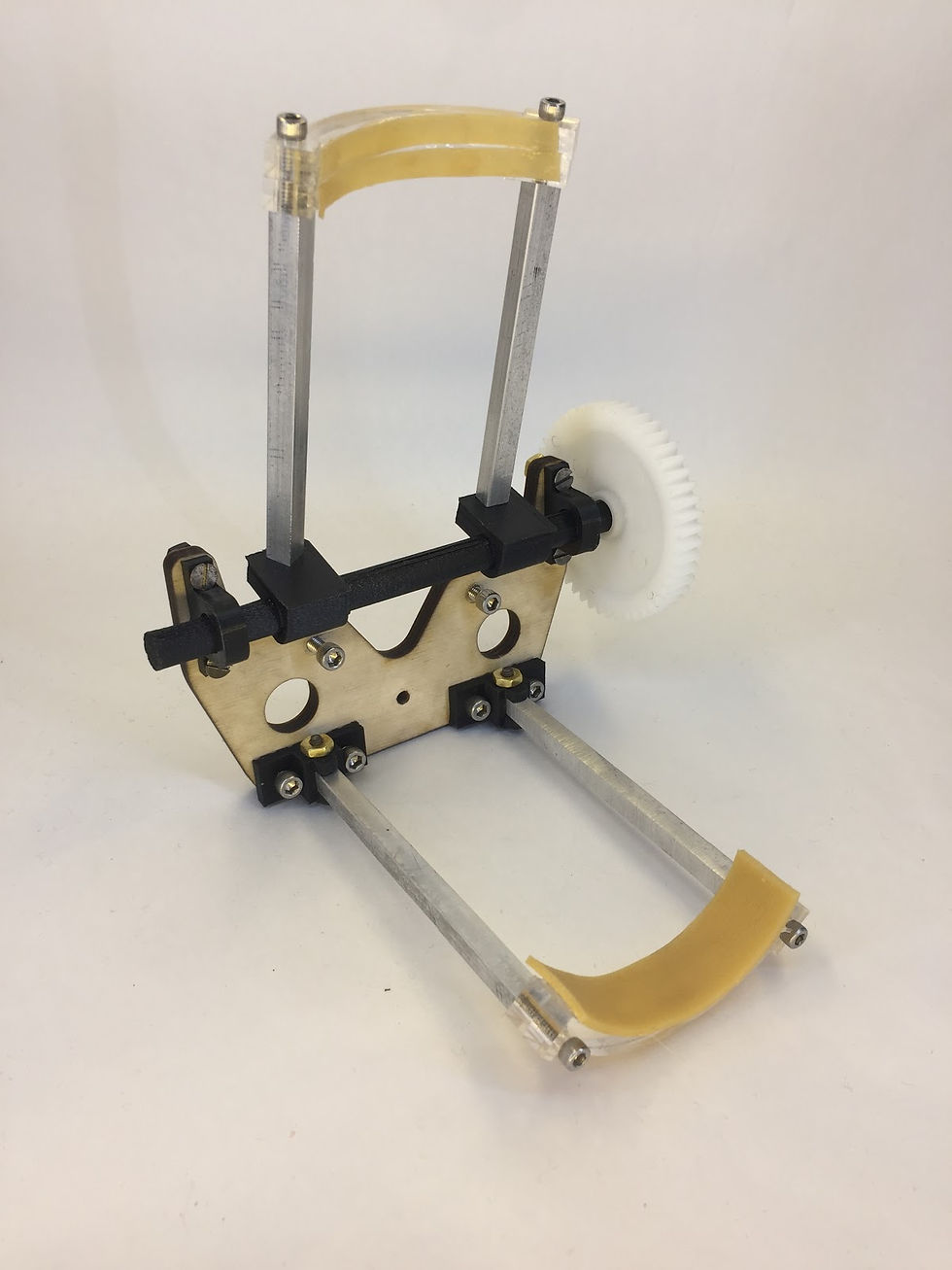

Full Assembly

Drawing of the Whole Assembly

Stress analysis of the vertical axle mount

Full Assembly

MANUFACTURING

A mixture of laser cutting, milling, and 3D printing were used to manufacture the gripper

I worked on the 3D printing aspect to ensure that there were sufficient supports and that the part was strong enough relative to the direction of the forces being exerted

Final Gripper

Drawing of the horizontal axle holder

Stress analysis of the horizontal axle holder

Final Gripper